PLEET

Simple and efficient data collection in your production

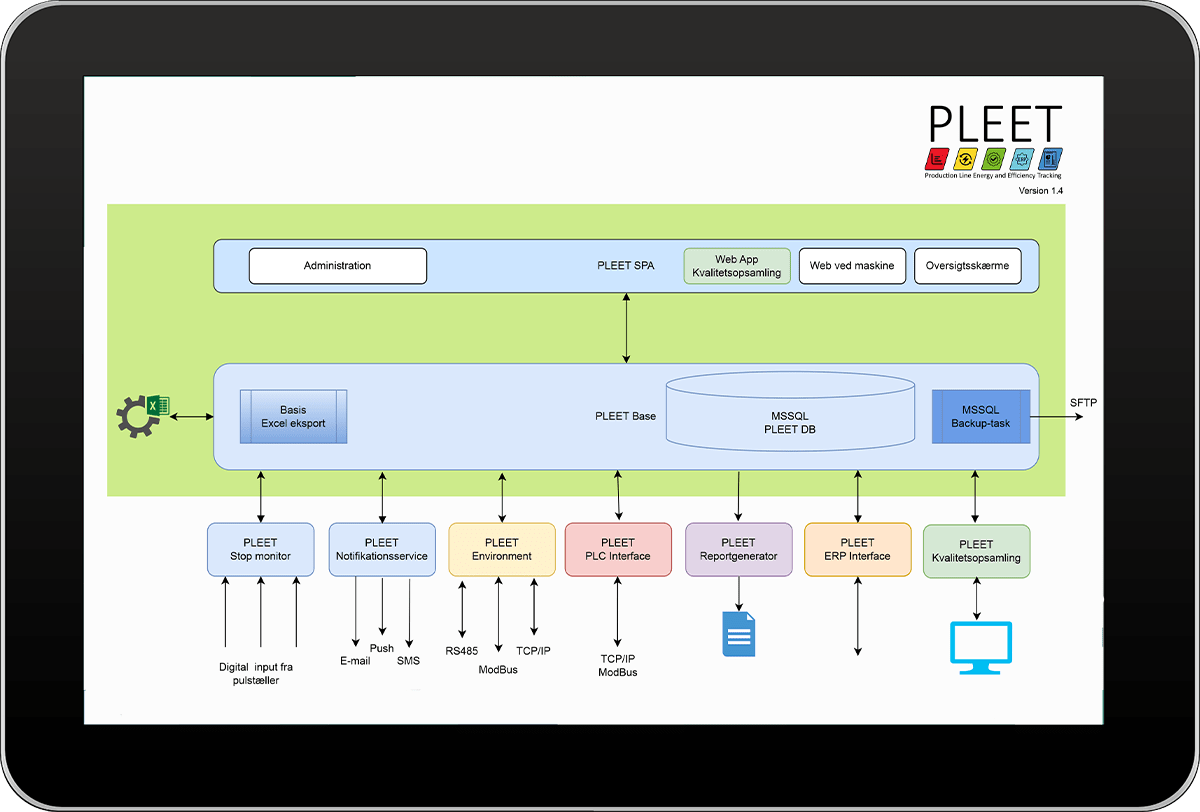

PLEET is an “out of the box” solution that, like building blocks, can be customized to your exact requirements, needs and wishes – without costing a fortune.

PLEET – In short

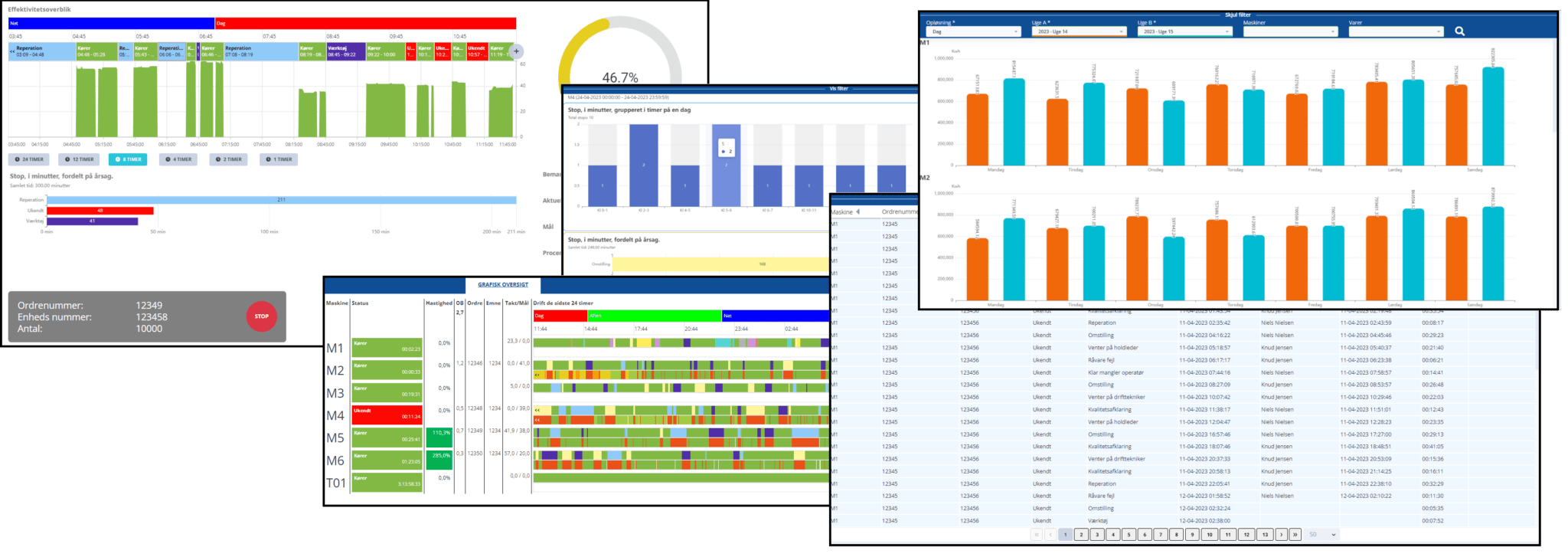

With PLEET, you can get data to make evidence-based decisions about your production. No guessing how much time a line is down or why it’s not performing as expected. With PLEET, you’ll see the bigger picture.

The system supports automatic or manual capture of machine stops and stop reasons. Subsequently, the system allows for analysis and reporting in an easy and intuitive way.

With PLEET, you get a system that can grow with you. PLEET can handle both stop causes, energy consumption and manage your quality management so you can get the right OEE numbers.

It’s all built in modules that can be added as the need for new functionality grows.

Be part of IoT 4.0 with PLEET

IoT 4.0 is the latest generation of the Internet of Things that uses 5G, AI and real-time data analytics to create intelligent and efficient solutions for different industries.

What about ESG?

With ever-increasing demands for ESG reporting, the desire to automate as much as possible is growing. And with PLEET, you get a tool that can automate the collection of energy consumption from your overall production – read more about the PLEET Enviroment module here

What’s all this about OEE?

We’ve boiled OEE down to 5 points that explain OEE quickly and accurately. Click on the arrows to unfold the explanation.

Identification of inefficiencies

Measuring OEE gives an indication of how efficiently production equipment is being used. If OEE is low, it may indicate that there are inefficiencies somewhere in the production process that need to be identified and eliminated to improve efficiency.

Optimizing the production process

By measuring OEE, you can gain a better understanding of where there is potential to optimize the production process. By focusing on areas with low OEE, you can implement improvements and increase the overall efficiency of the production process.

Reduction of costs

A higher OEE can result in fewer production stops, reduced production speed and less waste. This can lead to cost reductions in the form of less maintenance, fewer repairs and fewer products that need to be thrown away.

Improving production quality

High OEE can also help improve product quality. If production equipment operates efficiently and without interruption, it can lead to fewer defects and deviations from specifications.

Benefits of OEE

Overall, measuring OEE is a valuable way to assess the efficiency of production equipment and identify areas where improvements can be implemented. This can result in reduced costs, improved product quality and increased productivity.

Customer testimonial

“We have seen a significant increase in our production since we have installed PLEET. Production downtime has been reduced to such an extent that it has impacted our bottom line, and with the PLEET PFP module, we have digitized our production and removed all physical paperwork from production.

Our everyday life has just become so much easier since we got PLEET.”

– Claus Kvist, Plant manager, ST PLAST A/S

Click on the icons to read more about PLEET modules

Stop

Environment

PFP

ERP

Notify

Where should PLEET be installed?

PLEET can be installed as both an On-Premises solution on your current server system, or as a

Cloud solution

of your choice.

What you choose depends on your requirements and wishes. We are happy to provide guidance in your specific situation so that together we can find a solution that suits you.

Benefits of an

on-premises

installation:

- With an on-premises solution, you have full control over your data.

- Since both the database and PLEET are hosted on your own servers at the address, this can result in lower network latency and faster performance, especially when real-time processing is needed.

- On-premises solutions work independently of the internet connection. This can be important, especially in areas with unstable internet access.

- You can have more control over your systems and avoid unexpected changes or updates from third-party providers that can affect business operations.

Benefits of a Cloud installation:

- Cloud solutions allow you to scale your resources as needed. This makes it easy to adapt to changes in load and scale up or down without the need for large capital investment.

- Cloud providers are usually responsible for updating and maintaining infrastructure, freeing company staff from this task.

- Cloud providers have redundant systems and data centers, ensuring high availability and reliability. This is especially important for business-critical applications.

- Cloud providers usually invest significant resources in security and compliance with regulations and standards

Do you have any questions? – Contact us today