PLEET-PFP

The paperless production

PLEET PFP – The paperless production – Easy and efficient.

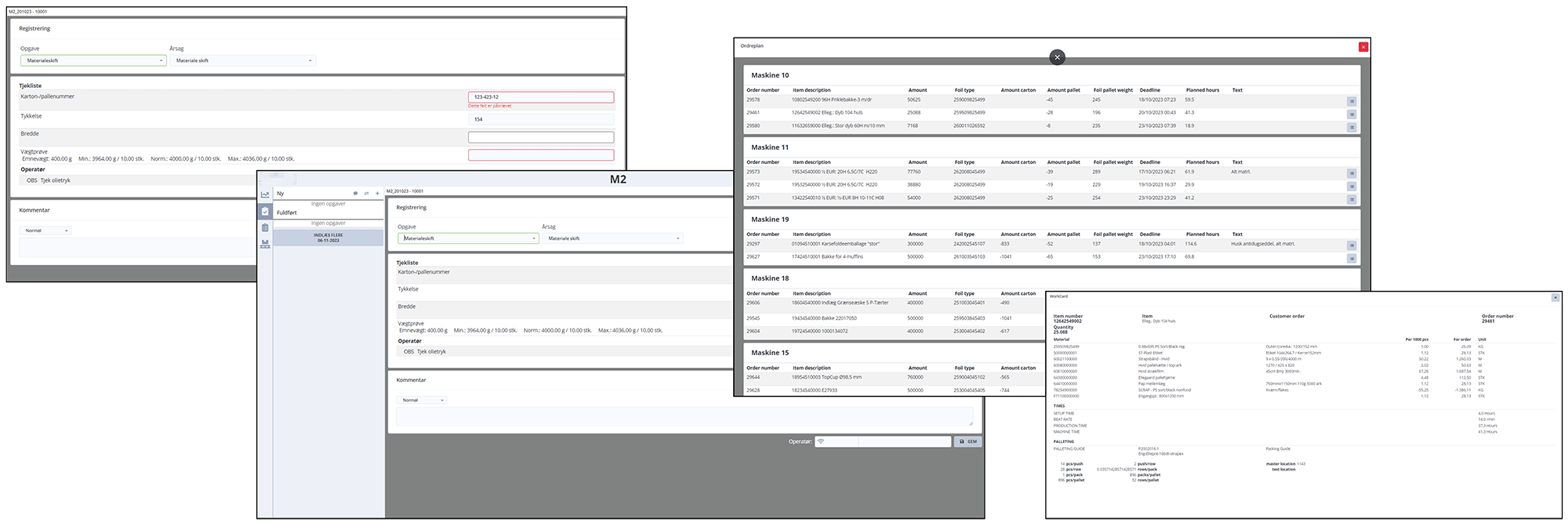

PLEET PFP module is quality assurance made simple. With our PLEET PFP module you can get rid of papers and notes lying around in production. The PLEET PFP module collects all the loose pages in a digital archive, so everything is in one place.

Digitizing the paper flow in a production process is an innovative approach that brings a number of benefits and improvements to the business. By replacing traditional paper-based procedures with digital solutions, you’ll experience increased efficiency, productivity and accuracy.

One of the key benefits is the significant time savings. By digitizing documents, work orders and reports, information becomes immediately available to all relevant parties. Eliminate the need to manually file, search and copy paperwork, freeing up resources and reducing unnecessary delays in production.

With the PLEET PFP module you get a highly flexible system that will fulfill most of your requirements for building a quality assurance system as standard.

With the PLEET PFP module you can build your own tests and quality schemes using a simple user interface. You can link to guides, manuals or drawings.

5 benefits of going paperless

Click on the arrows to unfold the explanations.

There is money to be saved

PLEET PFP module also enables more seamless communication and collaboration across departments. Everyone involved can easily access the necessary data and updates in real-time, promoting a more flexible and efficient workflow. This leads to reduced risk of misunderstandings and errors as everyone is working from the same up-to-date information.

The PLEET PFP module also improves data collection and analysis. When it’s all digital, it’s far easier to analyze to identify patterns, optimize processes and predict needs. This allows businesses to make informed decisions that can increase production quality and reduce waste.

Finally, the PLEET PFP module contributes to more sustainable production. Paper consumption is significantly reduced, lowering environmental impact and saving natural resources. In addition, digital processes can reduce the need for physical transportation of documents, further reducing a company’s carbon footprint.

Better data collection and analysis

By using digital tools, data can be collected and analyzed in real-time, allowing for better and more accurate monitoring of the production process. It helps identify inefficient processes and areas for improvement.

Reduction of costs

Paperless production can help reduce costs by eliminating the need for paper and other materials such as printer ink and toner. It can also reduce the cost of storing and archiving paper documents.

Better traceability and documentation

Digital documentation provides better traceability of the production process and contributes to more accurate documentation of production data. It also helps to ensure compliance with various standards and requirements that your business may be subject to.

Faster communication and decision-making

Digital tools and systems help reduce communication and decision-making delays as it’s easier to share and transfer information electronically. This leads to faster response times and increased efficiency.

Automate your paperwork

Automating your paperwork in production will give you significant direct savings on manual handling of documents.

No more loose papers in production. With

PFP module

it’s all digitized.

With PFP, you build your forms in an electronic format, eliminating the need to print physical forms.

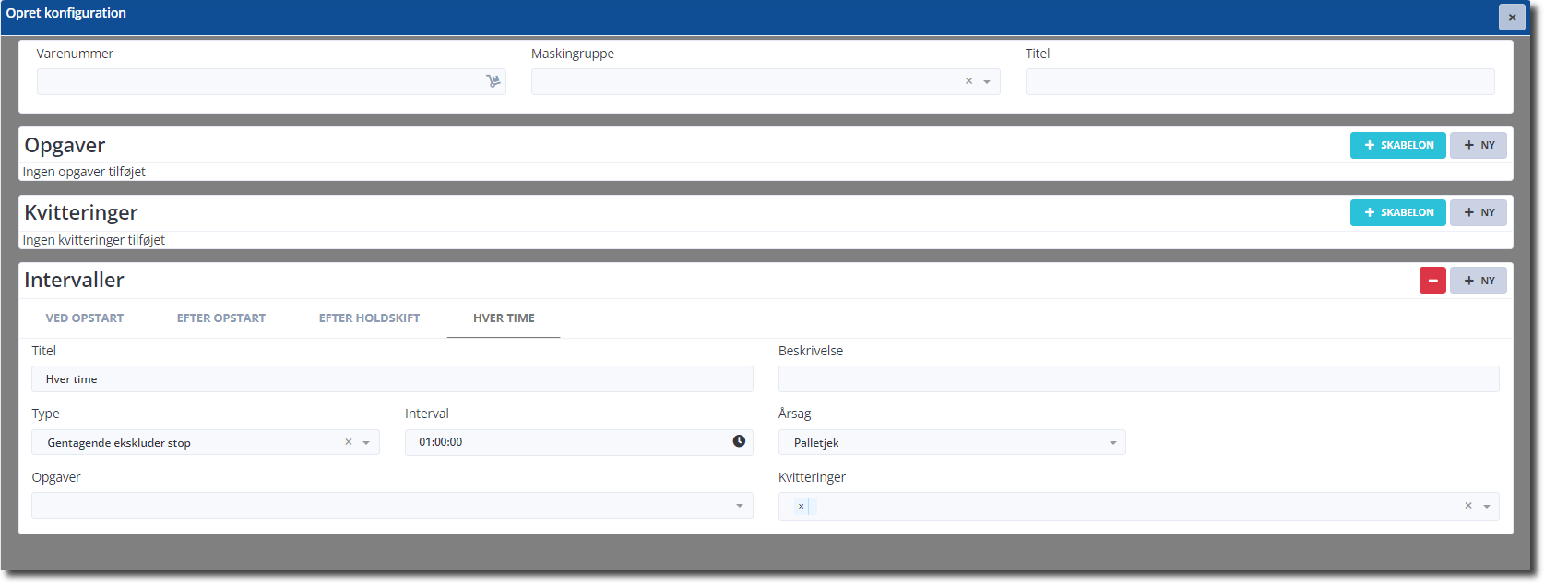

Quality scheme that easily adapts to new requirements and wishes

With our unique solution in PFP, you can quickly and easily build new forms by either reusing an existing form as a template or creating a new one.

You can decide at what interval a form should be completed and whether it should be signed by an additional employee.

Do you have any questions? – Contact us today