PLEET Stop

Register production stops and get an overview

PLEET Stop – Use PLEET to get an overview of your production stops

The details are where the truth lies – that’s why it’s important to know why things are the way they are and what you can do to change them. With the PLEET Stop module we can detect when and how long your production machine stops, and the operator can quickly and easily detect the cause with just one touch.

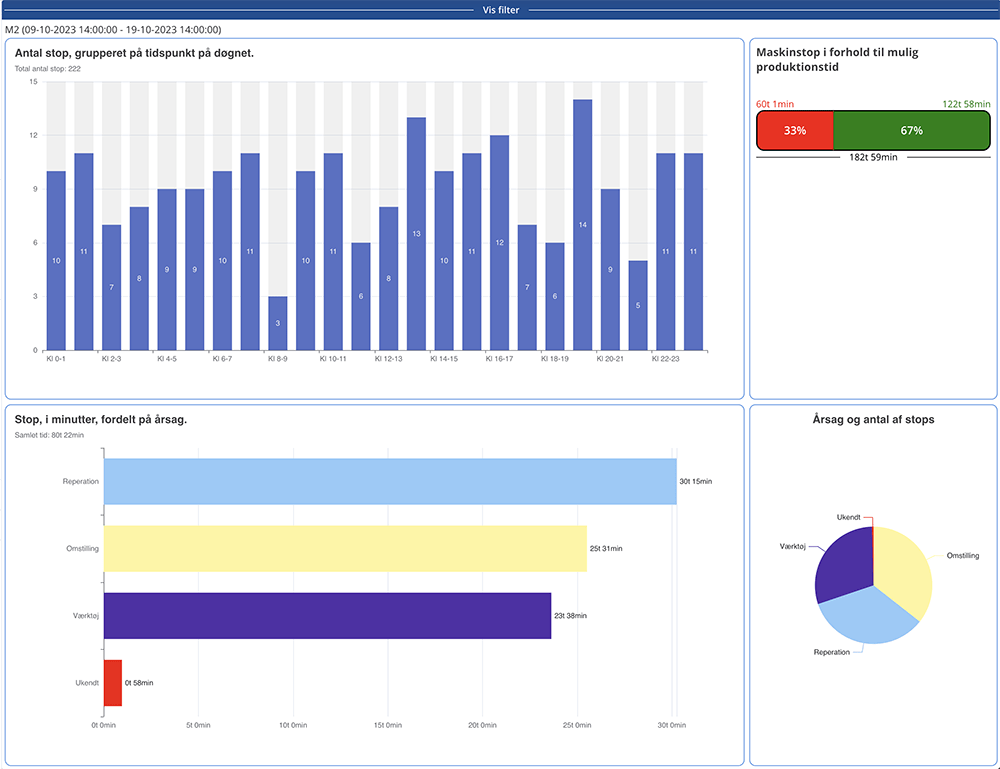

When you start to get an overview of the collected stops and categorize them into causes, you quickly start to see a pattern.

This is where PLEET proves its worth. With the unique and intuitive analytics tool, you can quickly and easily start analyzing the data you’ve collected and start planning actions to the most obvious causes of stops.

Knowing the cause of machine downtime helps ensure a more efficient, economical and reliable production process, which is crucial to maintaining competitiveness and success in many industries.

5 good reasons to know the causes of production downtime

Click on the arrows to unfold the explanations.

You can quickly restart production

Once you know the cause of the machine stoppage, you can quickly take the necessary measures to restore production. This reduces downtime and increases productivity, which can have a direct impact on your company’s bottom line.

You can minimize extra costs

Unplanned machine downtime can lead to increased costs due to lost production, overtime and possibly the need to repair or replace equipment. By knowing the cause, you can minimize these extra costs.

Easy to schedule maintenance

Knowing the cause of the machine downtime makes it easier to plan maintenance work and production schedules to avoid future interruptions.

It strengthens your business relationships

Constant machine downtime can affect your delivery time and reliability to customers and suppliers. Being able to handle these situations professionally and effectively strengthens your business relationships.

Avoid wasted time troubleshooting

By accurately diagnosing the problem, you can avoid wasting time and resources on fixing the wrong problems. This helps optimize the use of labor and spare parts.

Overview of the breakdown of causes for stops on each production machine

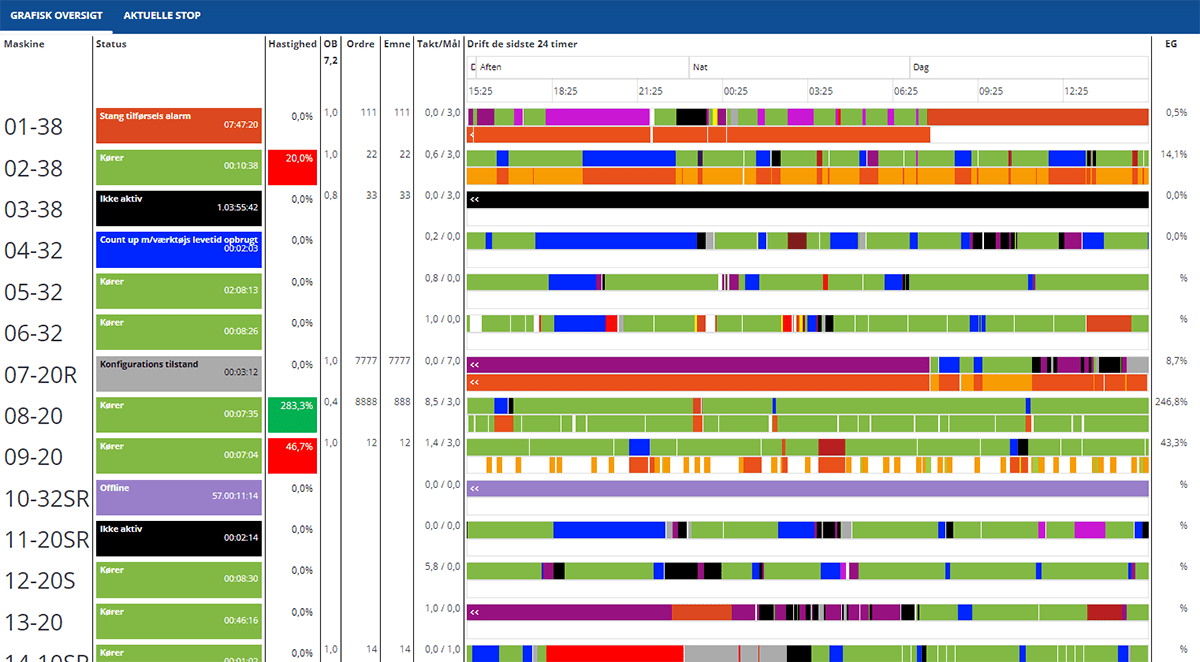

Real-time overview of production

Screen graphic at the individual machine

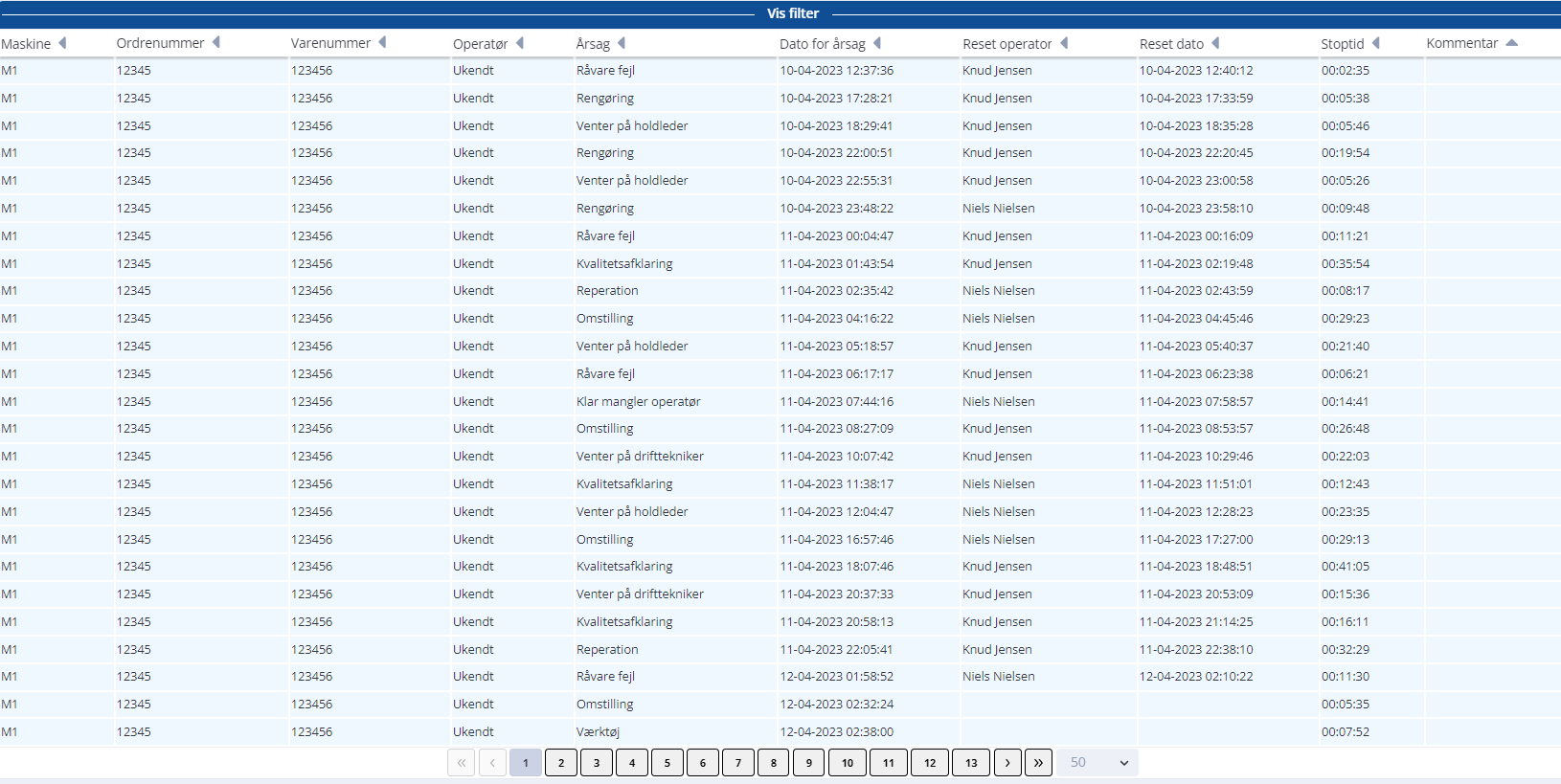

Extract statistics on stop causes for subsequent analysis in e.g. Excel.

How do you use PLEET to detect that the machine has stopped and to restore production?

There are basically three ways to see if your machine has stopped and to find the cause.

The choice of method in each situation depends on the type of machine, complexity and your requirements.

Method 1

An operator sees that it has stopped and now detects the cause by tapping the stop reason on the PLEET terminal.

Method 2

A PLEET input module is used, which detects that the driving signal disappears and the machine is therefore at a stop. The operator can then either immediately select the cause on the screen or later edit from “Unknown cause” to the actual cause.

Method 3

PLEET is directly connected to the controller in the machine. Through this, PLEET retrieves the current status. Here you can see if the machine is running, if the machine is in stop, PLEET can tell you the reason for the stop.

First step towards viewing your OEE

When we collect downtime and reasons for downtime, we have Part 1 for calculating OEE. Read more about digitizing your quality assurance in

PLEET PFP

so we can also capture your quality. When PLEET knows your production plan, it becomes a powerful tool. Read about how PLEET can be integrated with your ERP system below

PLEET ERP

.

Do you have any questions? – Contact us today